Inbound and outbound logistics form the backbone of supply chain logistics, defining how goods move from suppliers into businesses, and from businesses to customers. For supply chain companies in India and global enterprises alike, mastering these processes is critical to achieving cost savings, operational excellence, and customer satisfaction.

With the rise of integrated logistics management and digital innovations such as blockchain in supply chain and IoT-based visibility tools, businesses are rethinking traditional workflows. The goal is clear: enable faster order fulfillment, optimize costs, and improve resilience against disruptions.

What is Inbound Logistics?

Definition and Scope

Inbound logistics refers to the movement of raw materials, components, and supplies from suppliers to manufacturing plants, warehouses, or distribution centers. It focuses on procurement and sourcing, transport, receiving, and storage—ensuring the right inputs arrive at the right place, in the right condition.

Key Activities in Inbound Logistics

-

Procurement and Sourcing: Identifying, selecting, and managing suppliers to secure the best quality and price for materials. This involves negotiating contracts and building strong vendor relationships.

-

Supplier Management: Ensuring Supplier Reliability and Performance. This is crucial for mitigating risks associated with material shortages or delays.

-

Transportation: Managing the movement of goods from the supplier's location to your facility. This includes selecting carriers, optimizing routes, and tracking shipments.

-

Receiving: The process of unloading incoming goods, verifying their quantity and quality against purchase orders, and documenting their arrival.

-

Warehousing and Storage: Safely and efficiently storing received materials until they are needed for production or order fulfillment.

-

Material Handling: The use of equipment, such as forklifts and conveyors, to move, store, and control materials within the warehouse.

Why Inbound Logistics Matters

Effective inbound logistics reduces material shortages, prevents bottlenecks, and supports strategic logistics planning. For instance, in sectors like FMCG in the supply chain or automotive manufacturing, even a small delay in inbound supplies can halt production. By leveraging SCM vs Logistics insights, companies can align inbound flows with overall end-to-end supply chain management.

What is Outbound Logistics?

Definition and Scope

Outbound logistics refers to the distribution of finished goods from warehouses or production units to wholesalers, retailers, or directly to customers. It covers order fulfillment, last-mile delivery, and reverse supply chain flows when returns or exchanges occur.

Key Activities in Outbound Logistics

-

Order Fulfillment: The complete process from receiving a customer's order to preparing it for delivery. This includes order processing, picking, packing, and staging.

-

Inventory Management: Managing the stock of finished goods to ensure products are available when customers need them, without holding excess inventory.

-

Warehouse Operations: Managing the flow of goods within the warehouse for efficient picking and packing. This is where services like Custom Warehousing become critical.

-

Transportation: The physical movement of finished products to the customer. This can involve various modes, including trucking, rail, air, and ocean freight.

-

Last-mile delivery: The final leg of the delivery journey from a transportation hub to the customer's doorstep. This is often the most complex and costly part of the process.

-

Customer Service: Managing customer communication and resolving issues related to delivery or product condition.

Why Outbound Logistics is Critical

Outbound logistics directly impacts customer satisfaction and brand reputation. With the rise of quick commerce companies and hyperlocal delivery models, speed and accuracy in outbound logistics are becoming non-negotiable. For example, in e-commerce and retail, last-mile delivery is often the decisive factor for customer retention.

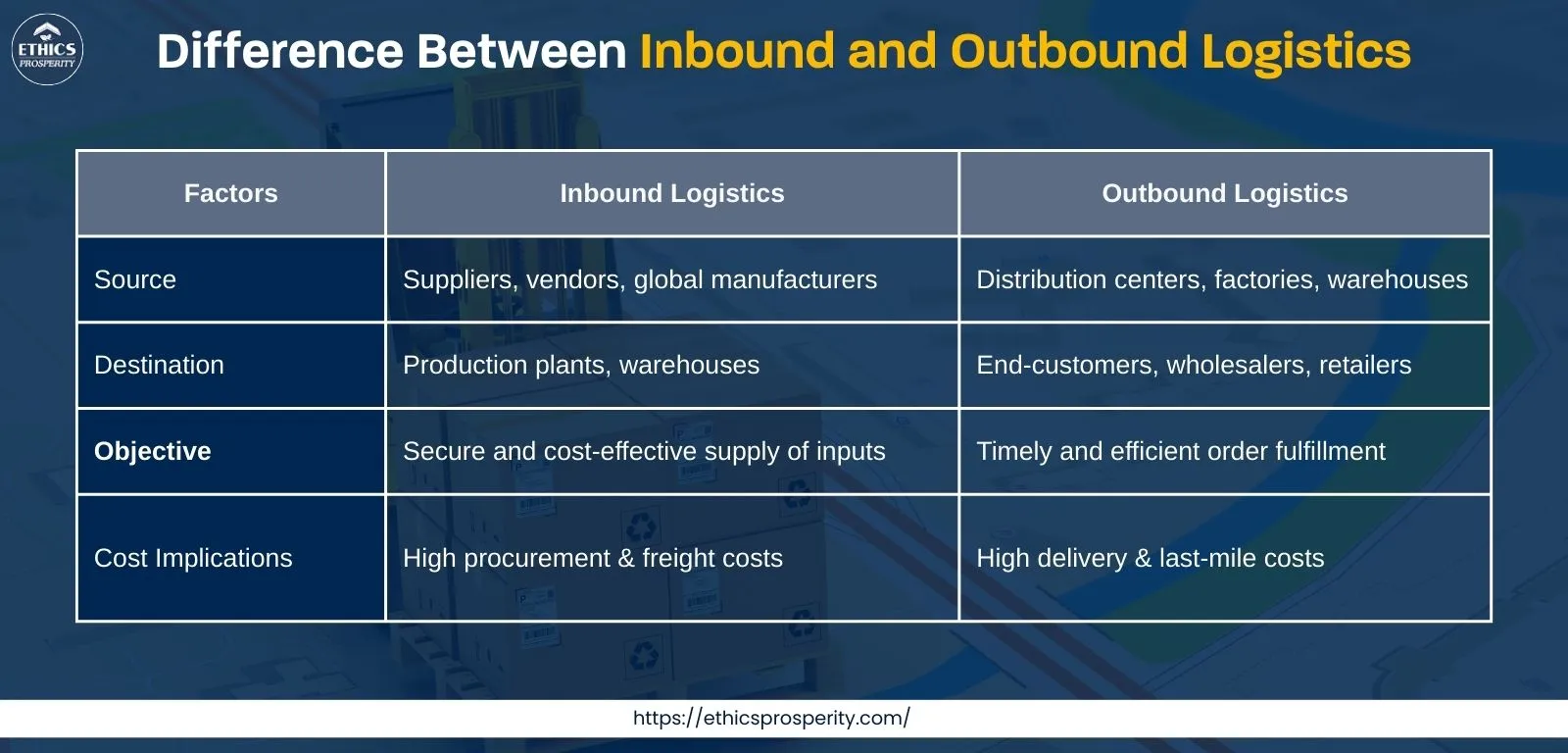

Key Differences Between Inbound and Outbound Logistics

1. Source

-

Inbound Logistics: Begins at suppliers, vendors, or global manufacturers who provide raw materials, components, or semi-finished goods.

-

Outbound Logistics: Originates from distribution centers, factories, or warehouses, where finished goods are ready for dispatch.

2. Destination

-

Inbound Logistics: Ends at production plants or warehouses, ensuring materials arrive where they’ll be stored or used for manufacturing.

-

Outbound Logistics: Ends with end-customers, wholesalers, or retailers, focusing on moving goods into the market.

3. Objective

-

Inbound Logistics: Main goal is to ensure a secure, consistent, and cost-effective supply of inputs, minimizing disruptions to production.

-

Outbound Logistics: Objective is timely, accurate, and efficient order fulfillment, which directly impacts customer satisfaction and retention.

4. Cost Implications

-

Inbound Logistics: Major costs include procurement, customs duties, and freight transportation, often influenced by global trade policies and supplier reliability.

-

Outbound Logistics: Costs are largely driven by last-mile delivery, carrier charges, packaging, and returns management, which can escalate quickly with rising customer expectations for speed.

Strategic Importance: Successful companies balance both sides, ensuring inbound stability supports seamless outbound execution. This is where custom warehousing and warehouse companies in India play a critical role.

Inbound and Outbound Logistics Process

An efficient Supply Chain Management operates as a single, cohesive system, not as a series of disconnected steps. The process flows from sourcing to final delivery.

-

Sourcing & Procurement: Identifying and purchasing materials.

-

Inbound Transportation: Shipping materials to the warehouse.

-

Receiving & Putaway: Unloading and storing materials.

-

Production/Manufacturing: Converting raw materials into finished goods.

-

Outbound Transportation: Shipping finished goods to the customer.

-

Last-Mile Delivery: The final leg of the journey.

-

Reverse Supply Chain: Handling returns and product recalls, which is an increasingly important part of the logistics process.

Technologies Powering Inbound and Outbound Logistics

The modern supply chain is driven by technology. Here are some of the most impactful solutions:

-

Warehouse Management Systems (WMS): These systems optimize storage, picking, and packing processes within a warehouse. They are crucial for both inbound receiving and outbound order fulfillment.

-

Transportation Management Systems (TMS): A TMS streamlines and automates the transportation process. It helps with route optimization, carrier selection, and real-time shipment tracking.

-

Enterprise Resource Planning (ERP): ERP systems integrate various business processes, from procurement to sales, providing a holistic view of the supply chain.

-

IoT and RFID for Real-time Tracking: The Internet of Things (IoT) and Radio Frequency Identification (RFID) provide real-time visibility into the location and condition of goods, enhancing security and transparency. The use of Blockchain in smart warehousing is also revolutionizing inventory and asset tracking.

Best Practices for Managing Inbound Logistics

-

Strategic vendor collaboration for reliable sourcing.

-

Shipment consolidation to reduce freight costs.

-

Advanced demand forecasting to align procurement with production needs.

Best Practices for Outbound Logistics

-

Automation in order fulfillment to reduce errors.

-

Optimized routing for cost-effective deliveries.

-

3PL partnerships to scale outbound reach, especially across global markets.

Challenges in Inbound and Outbound Logistics

The world of logistics is not without its hurdles.

-

Inbound Logistics Challenges:

-

Supplier reliability: Delays or quality issues from suppliers can disrupt the entire production schedule.

-

Geopolitical risks: Trade wars, political instability, and tariffs can impact the availability and cost of materials.

-

Rising freight costs: The cost of transportation is a constant challenge, particularly with fluctuating fuel prices.

-

Outbound Logistics Challenges:

-

Customer expectations: Customers demand faster, cheaper, and more transparent delivery options, putting pressure on logistics teams. This is a major factor in the growth of Quick Commerce Companies.

-

Last-mile delivery costs: The final leg of the journey is the most expensive due to a high number of stops and low drop density.

-

Reverse Logistics: Managing product returns efficiently is a complex challenge that requires a dedicated process.

Conclusion

Inbound and outbound logistics are the two pillars of supply chain logistics. Their effective integration drives cost efficiency, agility, and resilience. With innovations like blockchain in smart warehousing and AI-powered logistics planning, businesses can ensure real-time visibility, enhanced traceability, and improved customer experience.

For supply chain companies in India and beyond, adopting strategic logistics planning is no longer optional—it’s the key to staying competitive in a market shaped by E-commerce, quick commerce companies, and advanced digital ecosystems.