The majority of businesses nowadays have a complex structure so inefficiencies and a lack of transparency about constraints increases the cost and risk of whole supply chain. Hence, by providing smooth workflows, innovative apps, and real-time data, supply chain automation helps businesses enhance operations.

As Businesses may reduce inefficiencies, increase visibility, and maximize productivity without substantially raising operational expenses thanks to automation solution like robotic process automation, artificial intelligence (AI), and machine learning because manual supply chain process like data entry, inventory updates, and demand forecasting are labour-intensive and prone to error.

What is Supply Chain Automation?

Supply chain automation is the use of robotics, software, and technology to perform and improve supply chain operations with little or no human involvement. Its objective is to improve the speed, accuracy, and efficiency of the supply chain from obtaining raw materials to delivering final goods.

As per recent studies, The Indian logistics automation market size was valued at US $1,877.0 million in 2024, with a projected size of US $8,068.7 million by 2033 — a CAGR of ~ 15.7% during 2025-2033.

Benefits of Supply Chain Automation

Each business must stay updated of the most recent technological advancements and trends, including automation. These technologies have many benefits in addition to lowering the need for manual workers. Such benefits are:

Improved Accuracy

It guarantees that resources, products, and data flow correctly through each step of the supply chain and minimizes expensive errors. Some of the improvements are like real-time validation & error alerts, accurate inventory management, consistency in workflow, quality control & traceability.

Reduced Costs

One of the most obvious and quick advantages of supply chain automation is lower costs. Automation may significantly reduce both operational and strategic costs throughout the supply chain by eliminating repetitive manual tasks, streamlining logistics and reducing waste.

Better Inventory Management

One of the most important areas where supply chain automation significantly improves operations is inventory management, transforming manual, error-prone systems into intelligent, data-driven ones.

Automated inventory management uses technologies like RFID (Radio Frequency Identification), Warehouse Management Systems (WMS), Robotic process Automation (RPA), Artificial Intelligence (AI) & Machine Learning (ML) as these tools automatically track, record, and control inventory movement without any human intervention.

Increased Productivity & Efficiency

Supply chain automation can save time and costs by handling complicated data and processes more quickly and correctly than people because automation streamlines operations and repetitive activities, thus speeding up processes and reducing errors.

Businesses can experience a sharp increase in efficiency by integrating technology like machine learning into supply chain management, which further improves productivity.

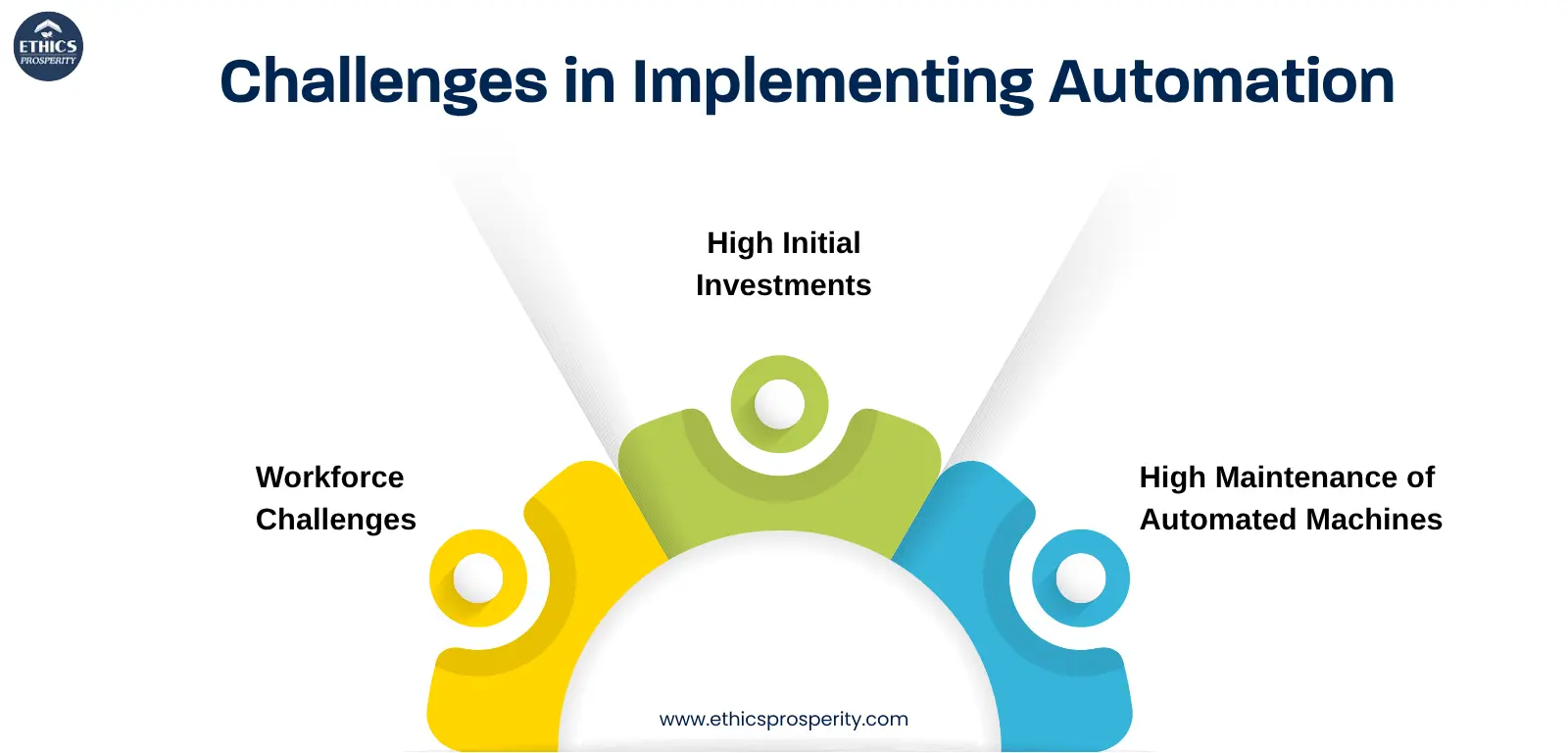

Challenges in Implementing Automation

Supply chain automation increases productivity, accuracy, and cost savings, but it requires careful planning, teamwork, a strong IT infrastructure and proactive risk management to be successful. Some of its challenges are:

-

Workforce Challenges: Even if jobs are not eliminated, employees may resist automation because it alters workflows and responsibilities. As automation can replace manual and repetitive tasks such as picking, packing, data entry or basic logistics operations.

-

High Initial Investments: Costs are not just associated with purchases; they also involve installation, customization, testing, and employee training. Since return on investment (ROI) is frequently long-term, businesses have to cover upfront expenses before collecting the rewards as high-capital costs can be prohibitive, especially for small and medium-sized companies.

-

High Maintenance of Automated Machines: Automated machinery, robots, and conveyor systems need expensive specialized tools, spare parts, and routine maintenance; thus, lack of expertise can lead to delayed repair or improper maintenance, reducing efficiency as even a short downtime can have a significant impact on inventory management and customer satisfaction.

Future Trends in Supply Chain Automation

Automation is quickly becoming an essential component of modern supply chain management. As it has been changing from warehouses to transportation; thus, the future of supply chain automation lies in intelligent interconnected and substantial ecosystems where robotics will continue to play an essential part in warehousing, with machines managing a wide range of complicated activities, making supply chains more quickly adaptable in the near future.

Some key automation trends are:

-

Robotic Process Automation (RPA): Robotic Process Automation (RPA) is the use of software robots to automate repetitive, rule based digital tasks that humans typically execute. This automation uses rule-based software to execute high volume business process activities, thereby liberating human resources to focus on more intricate duties. Some benefits of robotic process automation are rapid cost savings, higher customer satisfaction, better accuracy etc.

-

Automated Guided Vehicles (AGVS): Automated guided vehicles are autonomous, computer-controlled vehicles engineered to transfer materials, products, or goods within a facility. they operate without human assistance and travel along predefined routes that are indicated by wires, magnetic strips and sensors.

-

Drone Delivery in Last-Mile Logistics: The use of unmanned aerial vehicles to deliver goods straight to client’s locations is known as “Drone delivery” which is usually for the last-mile delivery (from warehouse or distribution centre to the end customer. This technology aims to make deliveries faster, cheaper, and more sustainable, especially in congested urban areas or remote locations where traditional transport is slow or costly.

CONCLUSION

The future of the supply chain sector is promising, as automation technology and artificial intelligence facilitate unparalleled efficiency and creativity. As the world advances rapidly, the need to adapt to the latest technologies is essential to remain competitive in the market. Hence, supply chain automation has become the new operating standard that drives efficiency, visibility, and resilience.

Automation transforms supply chains from expense centers into strategic investments by digitizing routine operations and integrating multiple systems. Now is the moment to explore supply chain automation to empower your business with the right tools and technologies and build a future driven by intelligent, automated operations.

At Ethics Prosperity, we help businesses embrace this transformation through end-to-end supply chain automation solutions — enabling smarter operations, reduced costs, and sustainable growth for the future.