In the modern supply chain landscape, Artificial Intelligence (AI) has moved from being an experimental tool to a core strategic enabler. Global disruptions, from the pandemic to port congestion, have shown that traditional supply chains — dependent on manual decision-making - can no longer deliver resilience, visibility, and agility.

Today, AI sits at the center of End-to-End Supply Chain Management, transforming operations from procurement to last-mile delivery. According to a 2025 Deloitte report, over 75% of leading supply chain companies in India have integrated AI-based forecasting, routing, and warehouse automation solutions to improve operational accuracy and reduce costs by up to 35%.

Understanding AI in Supply Chain Management

AI in supply chain management refers to the use of machine learning, predictive analytics, computer vision, and automation algorithms to optimize logistics, procurement, manufacturing, warehousing, and delivery operations.

It enables data-driven decision-making by learning from patterns across millions of data points - from supplier performance metrics to customer demand signals.

Core functions enhanced by AI include:

-

Real-time inventory forecasting

-

Predictive demand planning

-

Route optimization for logistics

-

Automated warehouse operations

-

Dynamic procurement and sourcing

When combined with Blockchain in Supply Chain and IoT-based visibility, AI ensures traceability, transparency, and trust, building a foundation for a more intelligent, connected ecosystem.

Why AI is Transforming Modern Supply Chains

AI drives transformation through automation, accuracy, and adaptability — the three pillars of modern logistics.

|

Area |

Before AI Implementation |

After AI Integration |

|

Forecasting Accuracy |

60–70% |

90–95% |

|

Operational Costs |

High manual dependency |

Up to 40% cost reduction |

|

Delivery Lead Time |

5–7 days |

Reduced to 1–2 days |

|

Order Fulfillment Accuracy |

85% |

98–99% |

|

Inventory Turnover Ratio |

3–4 cycles/year |

6–8 cycles/year |

Such measurable improvements have encouraged Supply Chain Companies in India to embed AI into Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and Custom Warehousing solutions.

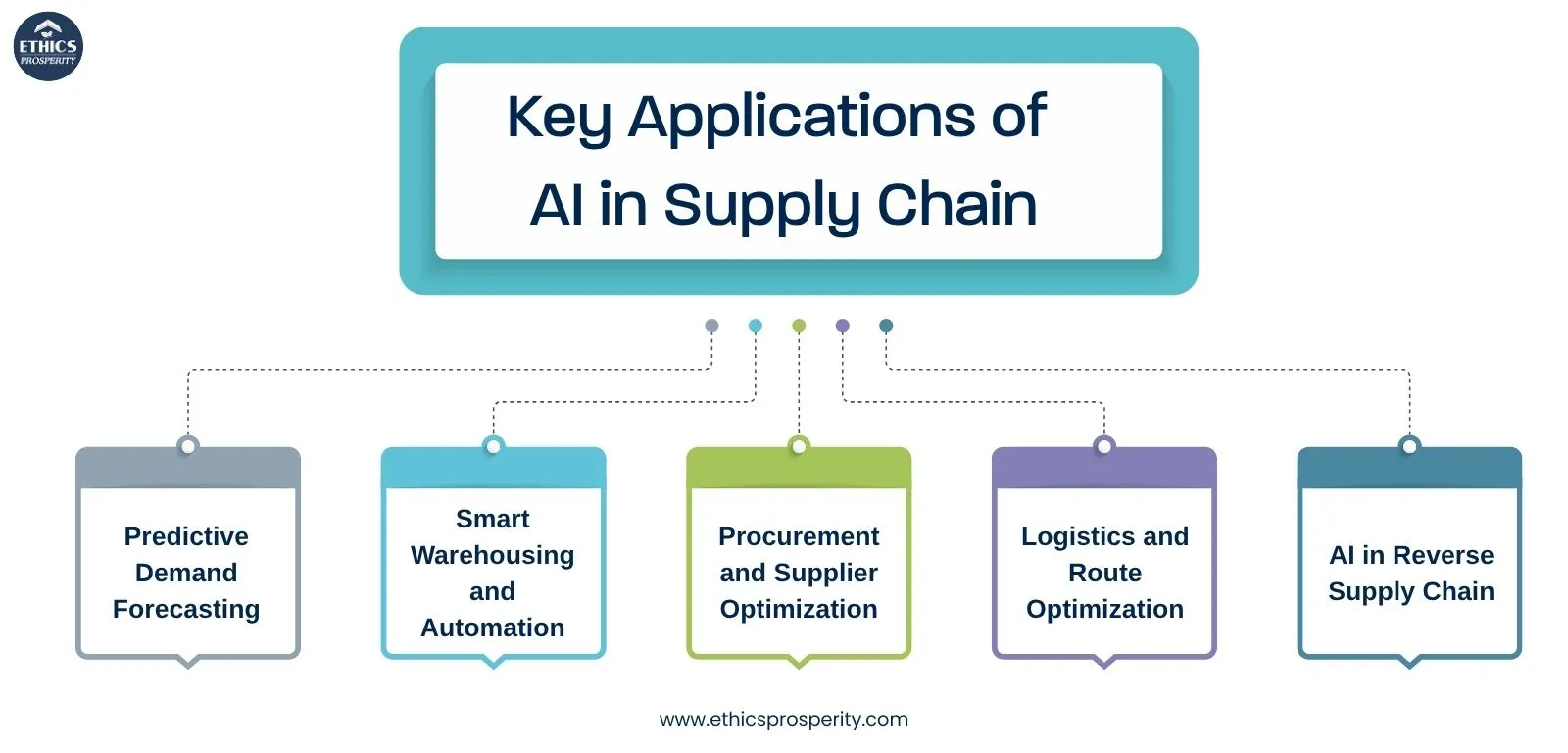

Key Applications of AI in the Supply Chain

(a) Predictive Demand Forecasting

AI enables real-time forecasting by analyzing historical sales data, weather patterns, and consumer trends. For example, FMCG leaders like HUL and ITC now rely on AI models that predict demand up to 12 weeks in advance, reducing stockouts and overstocking.

(b) Smart Warehousing and Automation

AI-driven warehouse automation integrates robotics, computer vision, and IoT sensors to enhance productivity.

Smart warehouses in India, such as those operated by Delhivery, Flipkart, and Ethics Prosperity, use:

-

Automated Guided Vehicles (AGVs)

-

AI-based picking robots

-

Computer vision for quality inspection

-

Machine learning algorithms for space utilization

These innovations boost throughput rates by up to 50% and lower operational errors by 70%.

(c) Procurement and Supplier Optimization

AI streamlines procurement by evaluating supplier risk, lead times, and cost-performance ratios.

Predictive sourcing platforms suggest alternate suppliers during disruptions — a capability crucial during global semiconductor shortages.

(d) Logistics and Route Optimization

AI helps logistics teams analyze traffic, fuel costs, and real-time shipment data to optimize delivery routes. Companies using AI-driven route planning report 15–20% lower fuel consumption and 25% faster delivery — enhancing customer satisfaction and sustainability.

(e) AI in Reverse Supply Chain

AI-based inspection systems automatically categorize returns for reuse, repair, or recycling, cutting reverse logistics costs by 30% and improving traceability.

AI-Powered Warehouse Management Systems (WMS)

An AI-powered WMS doesn’t just store data - it learns from it.

It continuously refines picking sequences, slotting algorithms, and workforce allocation.

Key features include:

-

Automated order batching and wave picking

-

Dynamic labor allocation based on workload forecasts

-

Predictive maintenance alerts for equipment

-

Integration with Blockchain in Smart Warehousing for secure transaction records

Ethics Prosperity’s End-to-End Supply Chain Management solutions integrate AI-driven WMS to improve visibility and synchronize inbound and outbound logistics efficiently.

AI and Last-Mile Delivery Optimization

Last-mile delivery - the most expensive segment of logistics - contributes nearly 53% of total shipping costs.

AI algorithms, combined with GPS and IoT data, enable dynamic rerouting, driver performance tracking, and demand clustering.

Example: Quick Commerce Companies in India like Zepto and Blinkit use AI to manage dark store fulfillment and optimize hyperlocal delivery networks.

This reduces average delivery time to under 15 minutes in major metro cities - a feat previously considered impossible in conventional models.

Benefits of AI in Supply Chain Management

|

Benefit |

Impact |

|

Real-time Visibility |

360° view across suppliers, inventory, and logistics |

|

Cost Efficiency |

Up to 40% reduction in operational costs |

|

Sustainability |

Lower CO₂ emissions via route and energy optimization |

|

Scalability |

Adaptable to business growth and seasonal surges |

|

Customer Experience |

Faster, accurate, and transparent delivery cycles |

With AI, Blockchain, and IoT, companies achieve predictive visibility — preventing issues before they occur.

Challenges and Future Outlook

Despite its benefits, AI adoption faces key challenges:

-

Data silos and lack of unified digital platforms

-

Shortage of skilled AI and analytics professionals

-

High implementation costs for small enterprises

However, the outlook is highly promising. By 2027, Gartner predicts AI-enabled supply chains will outperform competitors by 25% in efficiency and 30% in resilience.

Future-ready organizations like Ethics Prosperity are already integrating AI with Blockchain and Automation to build smarter, connected, and sustainable supply chains.

Conclusion

AI is redefining the future of supply chain management by turning reactive systems into predictive, intelligent ecosystems.

Whether it’s warehouse automation using AI, smart route planning, or intelligent demand sensing, AI ensures the supply chain of tomorrow is faster, smarter, and more sustainable.

Companies that act now — adopting AI-driven logistics, warehousing, and inventory management systems — will hold a decisive advantage in the coming decade.