Artificial intelligence allows machines to learn, analyze information, and make smart decisions similar to humans. In logistics, AI helps improve accuracy and streamline operations by supporting tasks like automated inventory, smarter planning, and better warehouse management. With light use of AI in logistics and supply chain automation, businesses can enhance efficiency across the supply chain.

AI is also changing how companies manage transportation and daily logistics activities. Through improved forecasting, route planning, and faster service, AI supports better decision-making and more reliable deliveries. These AI logistics applications help reduce costs, minimize waste, and build a more responsive and agile supply chain.

Understanding Artificial Intelligence in Logistics

Artificial intelligence in logistics refers to the use of advanced technologies that enable systems to analyze data, learn from trends, and make intelligent decisions that enhance overall supply chain performance. By integrating Artificial Intelligence supply chain capabilities, companies can achieve faster, more accurate, and more efficient operations across every stage of the logistics network.

Today, AI powers a wide range of AI logistics applications, including logistics optimization, AI in transportation, predictive logistics, AI warehousing, and supply chain automation. Through machine learning, robotics, and predictive analytics, AI helps automate repetitive tasks, improve routing, enhance demand forecasting, and streamline warehouse operations. These innovations enable logistics companies to operate with greater precision, reduce delays, minimize costs, and deliver a more responsive and customer-focused supply chain.

Overall, the rise of AI in logistics is reshaping how businesses move, store, and manage goods, creating smarter, more agile, and future-ready logistics systems.

Key Applications of AI in Logistics

Producers are adopting AI software to automate tasks like monitoring equipment failures, enhancing product quality, and accelerating shipments. Additionally, AI helps analyze large datasets to tackle complex logistics challenges. Below are some ways logistics managers leverage AI to meet their objectives:

-

Predictive Maintenance: AI monitors equipment to predict failures, reducing downtime and repair costs.

-

Quality Control: AI detects defects in real-time, ensuring consistent product quality.

-

Inventory Management: AI optimizes stock levels, preventing overstocking and shortages.

-

Route Optimization: AI plans efficient delivery routes, saving time and transportation costs.

-

Demand Forecasting & Decision Making: AI analyzes data to anticipate demand and improve supply chain decisions.

-

Warehouse Automation: AI-driven robots streamline picking, packing, and sorting tasks.

-

Customer Experience: AI tracks shipments and provides real-time updates, enhancing transparency.

Benefits of Artificial Intelligence in Logistics

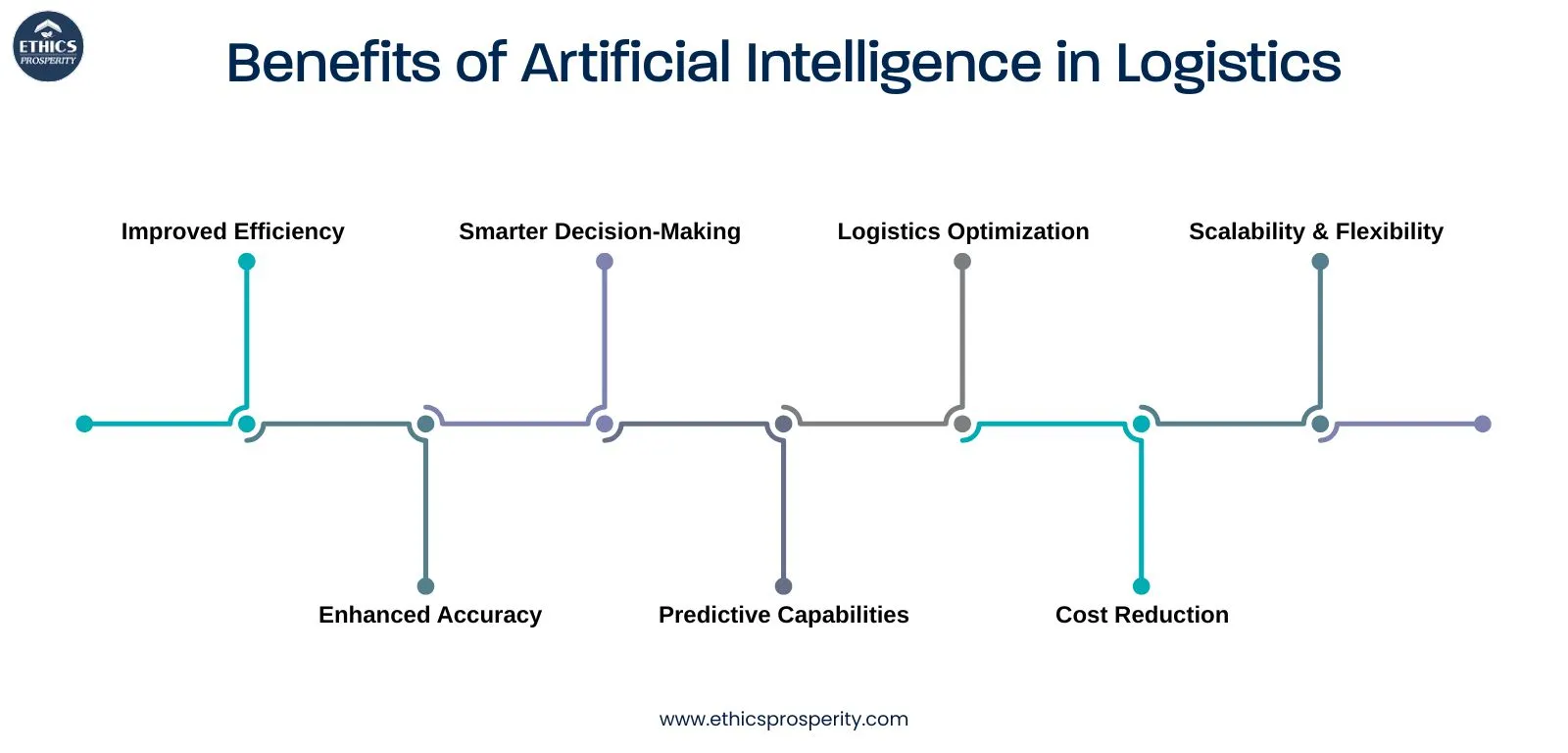

Artificial Intelligence (AI) in logistics is transforming the supply chain by offering numerous benefits that enhance operational performance. AI logistics applications, such as predictive logistics and AI in transportation, improve efficiency, accuracy, and decision-making. AI warehousing and supply chain automation enable logistics optimization, making the supply chain more streamlined, reliable, and responsive. Some of its benefits are:

-

Improved Efficiency: AI in logistics automates repetitive tasks like order processing, inventory updates, and shipment scheduling, allowing faster and smoother operations.

-

Enhanced Accuracy: AI logistics applications reduce errors in inventory management, demand forecasting, and quality control, ensuring reliable and consistent operations.

-

Smarter Decision-Making: Artificial Intelligence in the supply chain analyzes large datasets to provide actionable insights, helping managers make informed strategic decisions.

-

Predictive Capabilities: Predictive logistics enables companies to anticipate equipment failures, demand fluctuations, and potential disruptions, allowing proactive planning.

-

Logistics Optimization: AI in transportation and AI warehousing streamline routes, warehouse layouts, and resource allocation for faster deliveries and efficient operations.

-

Cost Reduction: Supply chain automation lowers labor, transportation, and operational costs by optimizing resources and reducing waste.

-

Scalability & Flexibility: AI solutions can easily scale to handle growing business needs, seasonal demand changes, and complex supply chain operations.

Challenges of AI Adoption in Logistics

While the benefits of AI in logistics are significant, implementing AI logistics applications comes with several challenges. Key issues include high implementation costs, data privacy and security concerns, workforce impacts due to automation, and regulatory and ethical considerations. Addressing these challenges is essential for businesses to successfully adopt predictive logistics, AI in transportation, AI warehousing, and supply chain automation while minimizing risks. Several challenges are :

-

High Implementation Costs – Investing in AI logistics applications, predictive logistics tools, and automation infrastructure can be expensive.

-

Data Quality and Availability – AI in transportation and AI warehousing relies on accurate, complete, and timely data for effective decision-making.

-

Integration with Existing Systems – Merging AI solutions with legacy supply chain systems or ERP platforms can be complex.

-

Skilled Workforce Shortage – A lack of professionals trained in AI logistics applications and supply chain automation can hinder adoption.

-

Cybersecurity and Data Privacy – AI systems handling sensitive logistics data are vulnerable to cyberattacks and breaches.

-

Change Management – Resistance from employees and management can slow the adoption of AI-driven processes.

-

Regulatory and Compliance Issues – Ensuring AI logistics applications meet legal, ethical, and industry standards is challenging.

-

Scalability Challenges – Scaling AI solutions across multiple warehouses, regions, or supply chain networks requires careful planning.

Future of AI in Logistics

AI is poised to revolutionize the logistics industry, with emerging trends and technological developments set to reshape operations. As AI continues to advance, it will drive greater efficiency, innovation, and sustainability, creating a more agile and responsive supply chain. Key trends and developments include:

-

AI Logistics Applications – Advanced AI tools will automate tasks such as inventory management, order processing, and shipment tracking.

-

Predictive Logistics – AI will anticipate equipment failures, demand fluctuations, and potential disruptions for proactive planning.

-

AI in Transportation – Intelligent route planning, traffic analysis, and autonomous vehicles will improve delivery speed and reduce costs.

-

AI Warehousing – Automated warehouses and robotics will streamline storage, picking, and packing processes.

-

Supply Chain Automation – End-to-end automation will enhance efficiency, reduce errors, and optimize resource utilization.

-

Data-Driven Decision Making – AI will analyze large datasets to provide actionable insights for smarter logistics strategies.

-

Sustainability and Green Logistics – AI will optimize routes, energy use, and resource allocation to reduce environmental impact.

Conclusion

Artificial Intelligence is reshaping the logistics sector by enabling smarter decision-making, logistics optimization, and an advanced artificial intelligence supply chain. As AI in logistics, predictive logistics, and AI warehousing continue to evolve, businesses can achieve greater efficiency, accuracy, and sustainability. Companies like Ethics Prosperity, embracing AI responsibly through transparency, data ethics, and fair workforce practices, ensures that innovation supports long-term prosperity. By balancing technological progress with ethical implementation, the logistics industry can build a resilient, future-ready, and customer-focused ecosystem.