Within business operations, the supply chain and value chain are commonly referenced frameworks used to assess efficiency, improvement opportunities, and customer impact. While they may appear aligned, understanding how they differ is crucial for organizations aiming to strengthen their competitive edge and refine operational workflows.

Hence, both play a vital role in the journey of creating, producing, and delivering products or services, but each emphasizes different components of how value is built and how goods reach the end customer.

What is a Supply Chain?

The supply chain represents the full process required to create and distribute a product or service, beginning with raw material sourcing and ending with delivery to the consumer. It serves as the operational backbone of any business, encompassing production, inventory oversight, transportation, and all logistics activities that ensure products reach their destination efficiently.

Supply Chain Management refers to the practice of planning and controlling supply chain activities. It is a cross-functional system that handles the flow of raw materials inside the organization as well as the movement of completed items out of the company, all while providing complete customer satisfaction. The supply chain includes the following activities:

-

Procurement – Acquiring the raw materials, products, or services needed for production.

-

Production / Manufacturing – Converting purchased materials into finished goods.

-

Inventory Management – Maintaining the right amount of stock to balance demand and costs.

-

Warehousing – Storing products safely until they are ready for distribution or sale.

-

Transportation – Moving goods between suppliers, facilities, and customers.

-

Order Fulfillment – Processing orders and preparing products for shipment.

-

Distribution – Delivering finished goods to retailers, distributors, or end users.

-

Returns Management (Reverse Logistics) – Managing product returns, repairs, recycling, or disposal.

What is a Value Chain?

The value chain represents the sequence of activities that add value throughout the process of creating, producing, and delivering a high-quality product to the customer. Value Chain Analysis involves examining the internal and external actions that contribute to a company’s ability to offer competitive, high-value goods and services at an optimal cost.

The concept of Value Chain Analysis was introduced by Michael Porter in his seminal 1985 book, “Competitive Advantage". Two key phases in the value chain analysis, in his perspective, are:

-

Individual activity identification

-

Assessing the value added in each activity and linking it to the firm's competitiveness.

The value chain process has five stages. They allow a company to generate value that exceeds the cost of supplying goods or services to consumers. Increasing activity in any of the five processes gives a corporation a competitive advantage over competitors in its industry. The five steps or activities are as follows:

-

Inbound Logistics – Receiving, storing, and managing raw materials and inputs efficiently.

-

Operations – Transforming inputs into finished products or services (manufacturing, assembly, etc.).

-

Outbound Logistics – Distributing finished goods to customers effectively (warehousing, transportation).

-

Marketing & Sales – Promoting products and persuading customers to buy (advertising, pricing strategies, sales).

-

Service – Providing support after purchase to maintain value (repairs, customer service, warranties).

Key Differences Between Supply Chain and Value Chain

|

Aspect |

Supply Chain |

Value Chain |

|

Purpose |

Efficient flow of materials and products. |

Creating more value for customers. |

|

Focus |

Cost reduction and smooth operations. |

Quality, innovation, and differentiation. |

|

Orientation |

Process-driven. |

Strategy-driven. |

|

Scope |

External network (suppliers to distributors). |

Internal activities (design to service). |

|

Activities |

Procurement, production, transport, and warehousing. |

Product design, branding, customer experience. |

|

Metrics |

Cost, speed, efficiency. |

Value, quality, competitive advantage. |

|

Flow |

Raw materials → final product → customer. |

Concept → value-added stages → customer experience. |

|

End Goal |

Deliver products at lowest cost and time. |

Deliver higher value than the cost of production. |

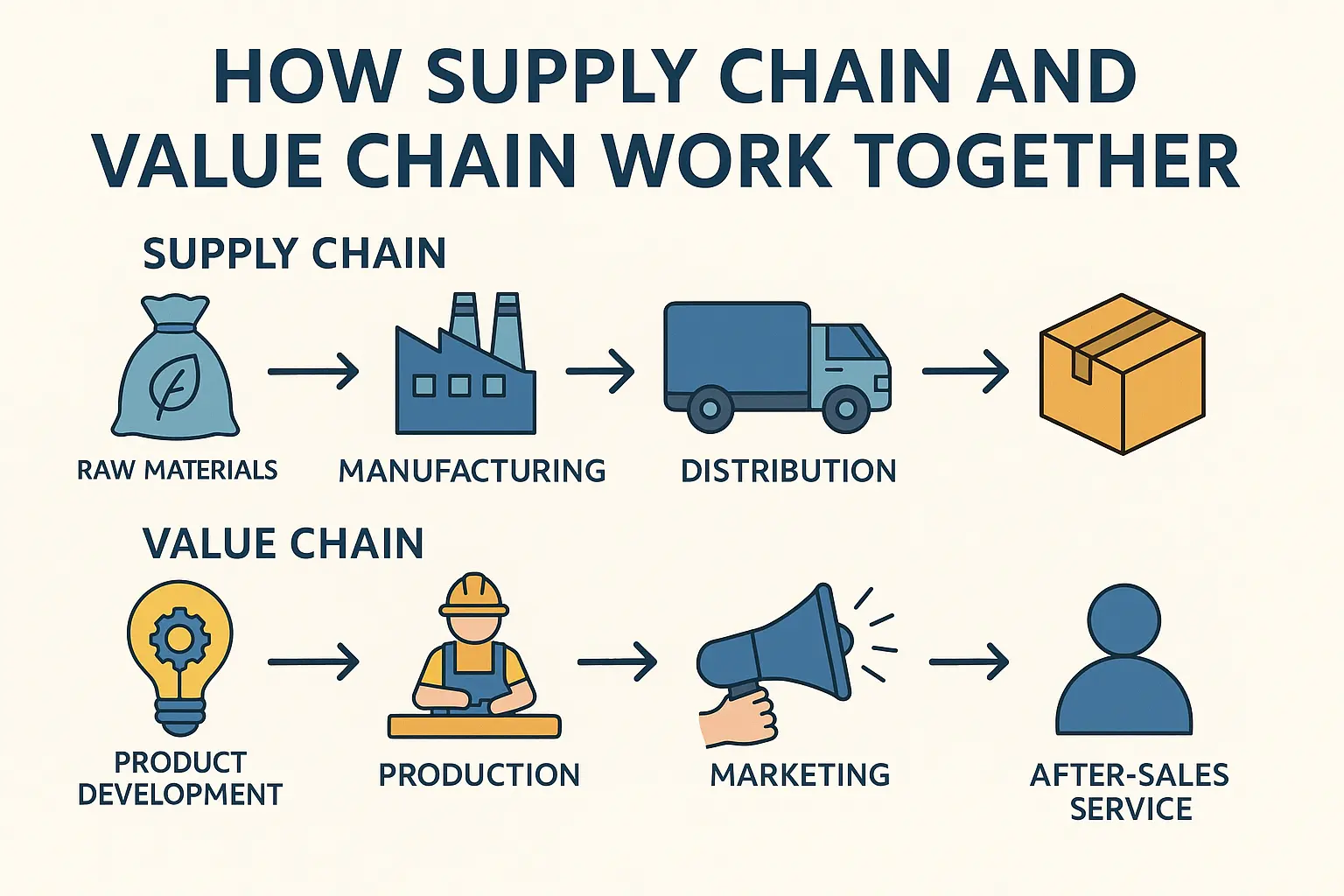

How Supply Chain and Value Chain Work Together

The supply chain and value chain work together as essential frameworks that help companies improve efficiency, strengthen business growth strategies, and deliver higher value to customers. The supply chain manages the full flow of materials, production, warehousing, logistics, and delivery, ensuring products move smoothly from suppliers to consumers. The value chain focuses on activities that increase product value including design, innovation, marketing, customer service, and quality management. When the supply chain and value chain operate in alignment, businesses can optimize operations, enhance product quality, and support stronger business growth strategies across competitive markets.

Integrating both the supply chain and value chain is crucial for organizations that want to scale operations and improve performance. A well structured supply chain reduces costs, improves speed, and boosts logistics efficiency, while a strong value chain enhances customer satisfaction, product differentiation, and market positioning.This combination helps organizations build powerful and sustainable business growth strategies that enable long term expansion.

A fully synchronized supply chain and value chain also help businesses respond faster to market changes, adopt new technologies, and innovate continuously. This alignment supports advanced business growth strategies by improving operational performance, increasing brand value, and boosting customer loyalty. Ultimately, the supply chain ensures efficient movement of goods, while the value chain ensures that every step adds meaningful value, working together to drive stronger, scalable, and sustainable business growth strategies for long term success.

Real-World Examples of Supply Chain vs Value Chain

1. Ethics Prosperity

Supply Chain: Provides structured logistics operations with efficient warehousing, distribution, and scalable transport solutions.

Value Chain: Delivers value through tech-enabled visibility, customer-focused services, and modern supply chain solutions designed for 2026 business needs.

2. Unilever

Supply Chain: Unilever coordinates global supply chain management for sourcing, production, and distribution of FMCG goods.

Value Chain: Sustainable sourcing, marketing, and packaging improvements enhance value, as seen in value chain analysis.

3. Samsung

Supply Chain: Samsung manages a complex supply chain for semiconductor production, assembly, and global distribution.

Value Chain: R&D, product innovation, and after-sales services increase value, confirmed through value chain analysis.

4. DHL

Supply Chain: DHL operates global supply chain management for logistics, warehousing, and express delivery.

Value Chain: Value is added through real-time tracking, reliable service, and customer-focused solutions in value chain analysis.

5. Walmart

Supply Chain: Walmart excels in supply chain management with large-scale procurement and automated distribution centers.

Value Chain: Low pricing, data-driven operations, and retail experience create value, supported by value chain analysis.

6. Amazon

Supply Chain: Amazon runs large fulfillment centers, uses automation for inventory, and manages fast delivery through an extensive logistics network.

Value Chain: Amazon adds value with personalized recommendations, Prime benefits, strong customer service, and a seamless shopping experience.

7. Toyota

Supply Chain: Toyota maintains a global supplier network, practices lean manufacturing, and uses just-in-time processes to minimize waste and keep production efficient.

Value Chain: Toyota differentiates through vehicle quality, safety features, R&D advancements (hybrid technology), marketing strategies, and customer service programs.

Conclusion

Understanding the difference between supply chain and value chain helps businesses improve efficiency and strengthen competitiveness. A clear supply chain definition focuses on the flow of goods and operations, while a strong value chain definition centers on adding value through innovation, marketing, and customer experience. Together, effective end to end supply chain management and insightful value chain analysis support powerful business growth strategies.

Real supply chain vs value chain examples show that companies like Ethics Prosperity succeed by integrating both systems to boost performance and deliver greater value. Aligning these two frameworks is essential for any modern business aiming to grow, innovate, and stay ahead in 2026 and beyond.