In today’s fast-evolving warehouse and logistics landscape, warehouse automation systems are redefining how businesses achieve speed, accuracy, and scalability. From robotics in warehousing and AI-enabled warehouse management systems to data-driven inventory management, automation is the foundation of smart warehouses designed for performance and resilience.

As demand grows for specialized solutions such as B2B warehousing & fulfillment, cold storage warehouses, and custom warehousing, leading warehousing companies in India are embracing advanced automation to streamline operations, reduce costs, and deliver consistent value across supply chains.

What Are Warehouse Automation Systems?

Warehouse Automation Systems are redefining the future of warehouse and logistics by bringing together robotics in warehousing, intelligent smart warehouses, real time Inventory Management, and a robust Warehouse management system to deliver faster, smarter, and more efficient operations.

From high performance B2B Warehousing & Fulfillment and temperature controlled Cold Storage Warehouse environments to tailored Custom Warehousing solutions, leading Warehousing Companies in India are leveraging automation to stay agile, scalable, and competitive in an evolving supply chain landscape.

Key Components of Warehouse Automation

Warehouse automation is driven by a set of integrated technologies that work together to streamline warehouse and logistics operations. These key components form the foundation of smart, efficient, and scalable warehouse automation systems.

1. Warehouse Management System – A Warehouse management system acts as the core of automation, enabling accurate Inventory Management, real time tracking, and seamless control across warehouse and logistics operations.

2. Robotics in Warehousing – Robotics in warehousing supports automated picking, sorting, and movement of goods, improving speed, safety, and efficiency in smart warehouses.

3. Automated Material Handling Systems – Conveyors, sorters, and automated storage solutions ensure smooth internal movement of goods within warehouse and logistics networks.

4. Inventory Management Technologies – Barcode scanning, RFID, and sensor based tools provide real time Inventory Management and improved stock accuracy across operations.

5. Smart Warehouse Infrastructure – Smart warehouses use integrated systems, sensors, and data analytics to enhance operational visibility and decision making.

6. Temperature Controlled Inventory Management – Automated systems ensure accurate Inventory Management in Cold Storage Warehouse operations, maintaining product integrity while supporting efficient warehouse and logistics workflows.

7. Custom Warehousing and Fulfillment Solutions – Automation supports Custom Warehousing and B2B Warehousing & Fulfillment requirements, enabling Warehousing Companies in India to scale operations efficiently.

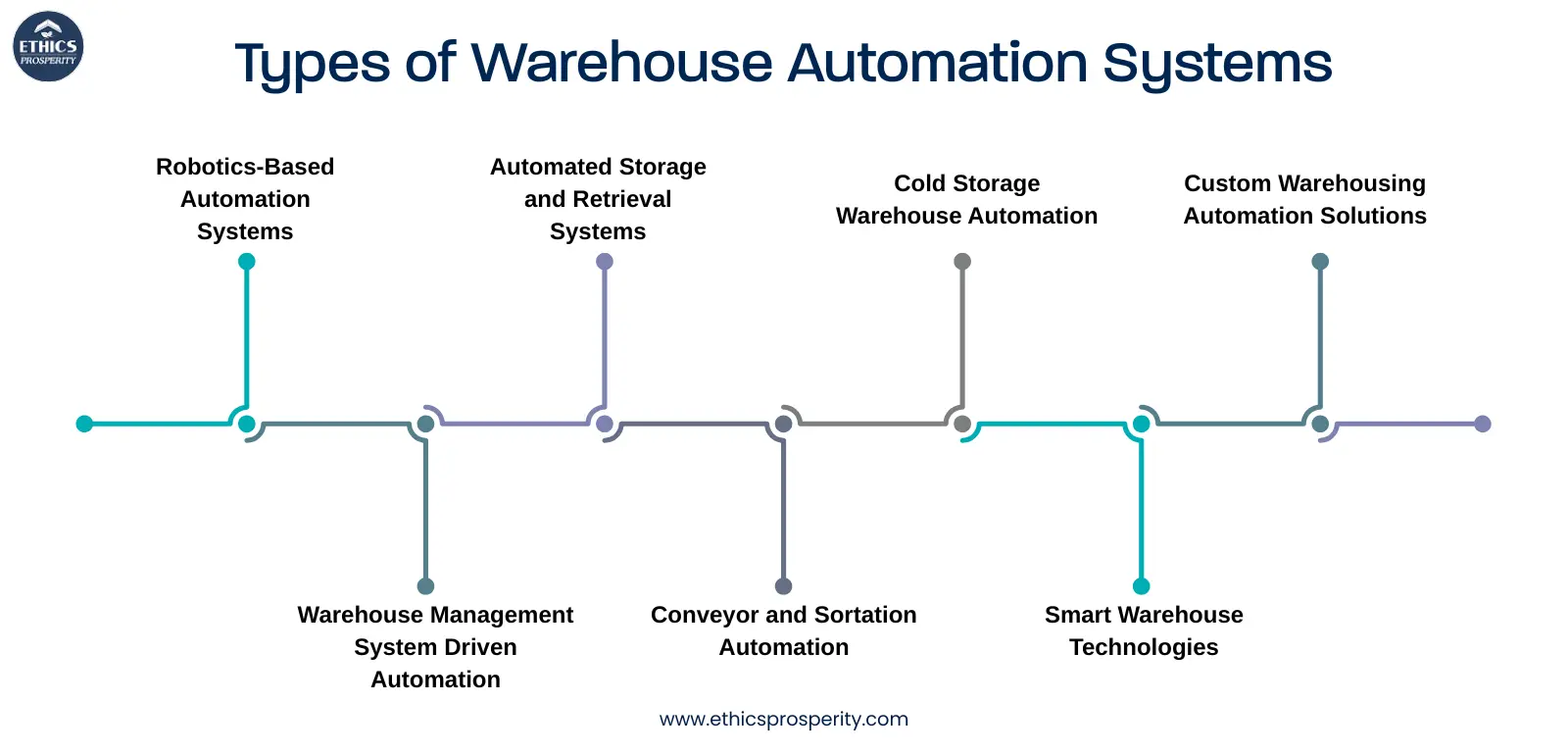

Types of Warehouse Automation Systems

Warehouse automation systems encompass a range of technologies designed to streamline warehouse and logistics operations with greater speed and accuracy. Each type plays a specific role in building smart, efficient, and scalable warehouses.

1. Robotics-Based Automation Systems – Robotics in warehousing automates picking, sorting, and material movement, helping smart warehouses improve speed and accuracy across warehouse and logistics operations.

2. Warehouse Management System Driven Automation – A Warehouse management system enables seamless Inventory Management, order processing, and real time visibility for efficient B2B Warehousing & Fulfillment.

3. Automated Storage and Retrieval Systems – These systems optimize storage density and streamline Inventory Management while supporting scalable warehouse and logistics workflows.

4. Conveyor and Sortation Automation – Designed for high volume operations, these systems support fast movement and dispatch of goods in B2B Warehousing & Fulfillment environments.

5. Cold Storage Warehouse Automation – Automation solutions for Cold Storage Warehouse facilities ensure temperature control, compliance, and efficient handling of sensitive products.

6. Smart Warehouse Technologies – Smart warehouses use sensors, data, and automation to enhance operational intelligence and decision making.

7. Custom Warehousing Automation Solutions – Custom Warehousing automation allows Warehousing Companies in India to tailor systems based on industry needs, product types, and business scale.

Benefits of Warehouse Automation Systems

Warehouse automation systems bring transformative benefits to warehouse and logistics operations by leveraging robotics in warehousing, smart warehouses, Inventory Management, and a robust Warehouse management system. Some of its benefits are:

1. Increased Efficiency – Automation speeds up processes like picking, packing, and sorting, improving productivity across B2B Warehousing & Fulfillment, Cold Storage Warehouse, and Custom Warehousing operations.

2. Improved Accuracy – Advanced Inventory Management and automated systems reduce human errors, ensuring precise stock tracking and order fulfillment.

3. Cost Savings – By optimizing workflows and reducing manual labor, automation helps Warehousing Companies in India cut operational costs while scaling effectively.

4. Better Space Utilization – Automated storage and smart layouts in smart warehouses maximize space, allowing more goods to be stored efficiently.

5. Enhanced Safety – Robotics in warehousing and automated material handling reduce workplace hazards, creating a safer environment for staff.

6. Real-Time Visibility – A Warehouse management system provides real time tracking of inventory, shipments, and overall warehouse performance.

7. Scalability and Flexibility – Automation supports dynamic operations in B2B Warehousing & Fulfillment, Cold Storage Warehouse, and Custom Warehousing, helping businesses scale as demand grows.

Warehouse Automation Use Cases by Industry

Warehouse automation systems are transforming warehouse and logistics operations across industries by leveraging robotics in warehousing, smart warehouses, Inventory Management, and advanced Warehouse management systems. Some of its benefits to several industries are as follow:

1. E-Commerce and B2B Fulfillment – Automation accelerates order picking, packing, and shipping, optimizing B2B Warehousing & Fulfillment while ensuring accurate Inventory Management in fast-moving smart warehouses.

2. Cold Storage and Food Industry – Automated Cold Storage Warehouse solutions maintain temperature control, reduce product spoilage, and streamline warehouse operations with minimal manual handling.

3. Pharmaceuticals and Healthcare – Smart warehouses equipped with Inventory Management systems and robotics ensure secure, compliant, and efficient handling of sensitive medical products.

4. Retail and Consumer Goods – Automation enhances speed, accuracy, and space utilization for large-scale storage, replenishment, and dispatch in Custom Warehousing and smart warehouses.

5. Manufacturing and Automotive – Automated storage, retrieval, and material handling systems improve workflow efficiency, inventory tracking, and supply chain coordination across warehouse and logistics operations.

6. Third-Party Logistics (3PL) Providers – Warehousing Companies in India use automation to offer scalable, accurate, and high-speed services to clients across sectors, from B2B Warehousing & Fulfillment to cold chain logistics.

Conclusion

Warehouse automation systems are redefining modern warehouse and logistics operations by integrating robotics in warehousing, intelligent smart warehouses, advanced Inventory Management, and a robust Warehouse management system. From B2B Warehousing & Fulfillment and Cold Storage Warehouse operations to flexible Custom Warehousing solutions, automation enables higher efficiency, accuracy, and scalability across supply chains.

As one of the forward-looking Warehousing Companies in India, Ethics Prosperity is committed to adopting innovative automation technologies that strengthen operational excellence and support long-term, sustainable growth for its customers.